The growing popularity of whole-home customization stems not only from rising living standards but also from its ability to deliver highly personalized designs and maximize space utilization. In other words, modern home furnishings increasingly rely on engineered panels.

Customized panels are composed of a substrate plus a surface finish. Today, let’s start with the substrate and explore the differences between commonly used substrates such as particle board, MDF, plywood, and FOSB.

MDF(Medium Density Fiberboard)

MDF is made from wood fibers or other plant-based fibers combined with urea-formaldehyde resin or other suitable adhesives. In simple terms, it is produced by compressing wood powder with adhesive. Raw materials typically include recycled wood, tree branches, and formaldehyde-based adhesives.

Based on density, it can be classified into High-Density Fiberboard (HDF), Medium-Density Fiberboard (MDF), and Low-Density Fiberboard (LDF). In whole-home customization, Medium-Density Fiberboard (MDF) is the most commonly used, with a density range of 650 kg/m³ to 800 kg/m³.

MDF(Medium Density Fiberboard)

MDF offers a smooth and uniform surface with fine texture, making it highly suitable for decorative finishes. Its excellent workability allows it to be easily shaped into various designs, and it takes well to painting and coating. As a result, it is often used as a substrate for cabinet doors in classical or European-style interiors.

However, MDF has relatively poor moisture resistance and low impact strength. In addition, its nail-holding capacity is limited; if a screw becomes loose, it is difficult to refasten in the same position. Therefore, MDF is generally only suitable for cabinet doors in dry areas and is not recommended for cabinet cases.

PB(Particle Board)

PB is manufactured by shredding materials such as twigs, small-diameter logs, fast-growing timber, wood chips, and veneer scraps into fragments of specified sizes. These fragments are then dried, mixed with adhesives (such as urea-formaldehyde resin), hardeners, and water repellents, and pressed under heat and pressure to form panels.

In today’s market, some particle board manufacturers use low-cost urea-formaldehyde adhesives to reduce production costs, which can lead to excessive formaldehyde emissions. Consumers are advised to exercise caution and verify product certifications when selecting particle board.

PB(Particle Board)

Particle board has a uniform internal structure with similar strength in all directions. It offers a flat surface that is suitable for various laminating processes, is easy to work with, and provides good sound absorption and insulation properties. It is also cost-effective, making it a popular choice for budget-conscious applications.

However, due to its irregular internal composition, particle board has moderate nail-holding capability when first fastened but performs poorly if screws are reinsterted. Its strength and dimensional stability are relatively low, and it is prone to swelling and deformation when exposed to moisture. As a result, it is generally only used in dry areas for cabinet cases and doors with low load-bearing requirements.

Plywood

Plywood is produced by peeling logs into veneers or slicing wood into thin sheets, which are then bonded with adhesive into a panel structure with three or more layers. Typically, an odd number of veneer layers are used, with the grain direction of adjacent layers arranged perpendicular to each other to enhance strength and stability.

Plywood

Plywood offers relatively high strength, good workability, stability, and moisture resistance. Its smooth surface is well-suited for decorative finishes and painting. However, it is relatively heavy, which can complicate handling and installation.

A significant challenge in production is controlling the amount of adhesive used, which directly affects formaldehyde emissions. It is essential to choose products that meet at least the national E1 standard. Plywood is generally suitable for kitchen and bathroom cabinet cases, as well as cabinet doors that are not excessively tall or wide.

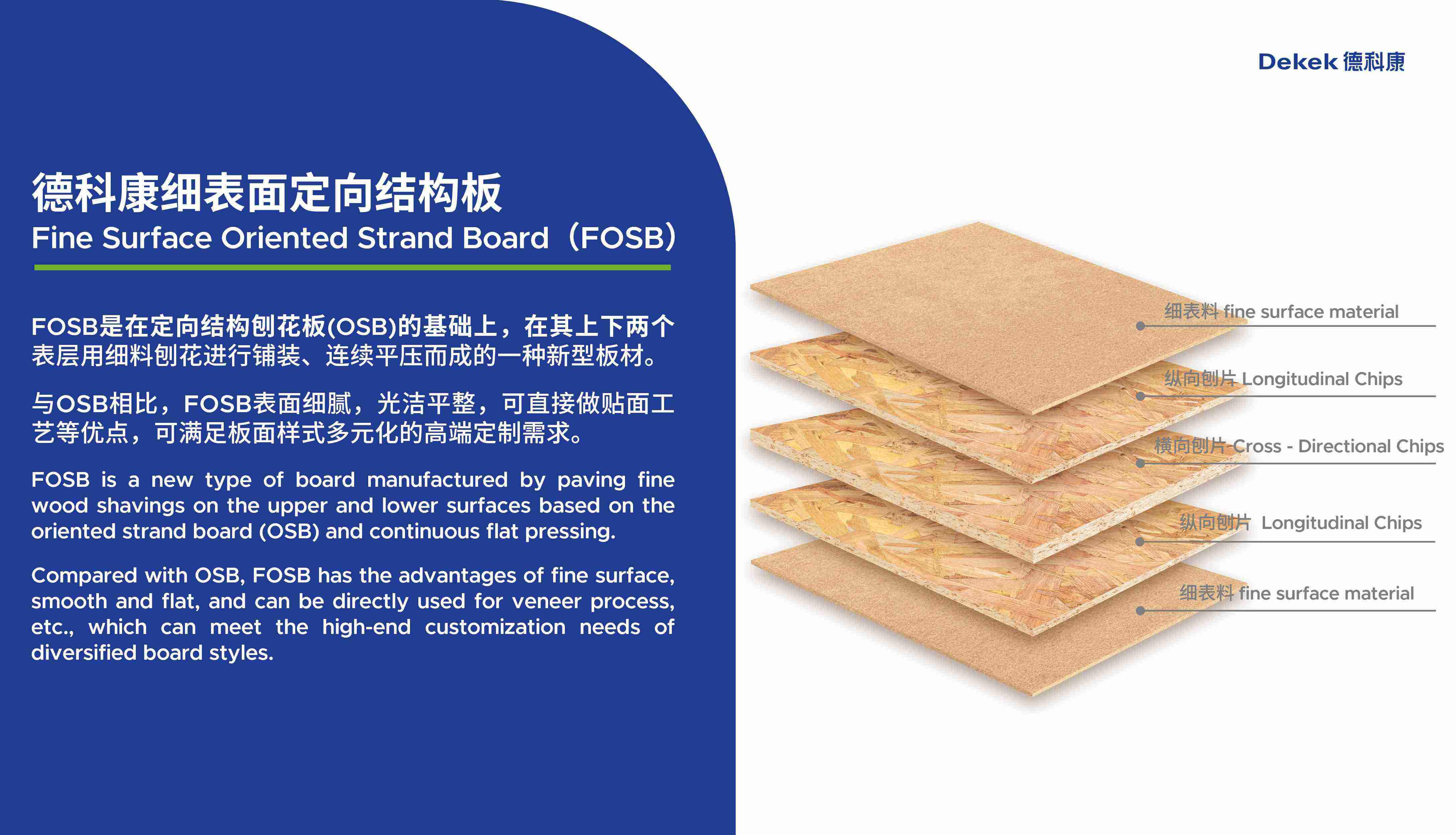

FOSB (Fine Surface Oriented Strand Board)

FOSB is an environmentally friendly panel produced through continuous hot pressing. Its core layer consists of horizontally aligned strands, while the two middle layers feature vertically oriented strands, creating a regular and stable internal structure. The surface is refined with a fine-layer material and sanded smooth, allowing direct veneer application and meeting high-end customization needs for diverse surface designs.

Moreover, Dekek FOSB is produced using large-sized strand flakes and formaldehyde-free MDI adhesive as raw materials. The manufacturing process incorporates no waste, recycled materials, or added formaldehyde, enabling the product to meet China’s stringent new ENF environmental standard.

In addition to its eco-friendly properties, Dekek FOSB offers high moisture resistance, exceptional dimensional stability, strong nail-holding capacity, and high load-bearing performance. It has also obtained all the authoritative certifications, underscoring its quality and reliability for demanding applications.

In summary, decorative panels using moisture-resistant FOSB as a substrate are suitable for full-scene home customization applications, such as floor-to-ceiling wardrobe doors, bathroom vanities, kitchen cabinets, and panel furniture. The main limitation is its higher requirement for installation precision. Dekek Group maintains its own R&D team and operates the largest FOSB production base in Guangdong and Guangxi,China. We are continuously improving our product and service offerings while deepening our understanding of the market to produce more environmentally friendly and user-friendly panels that meet the needs of modern households.

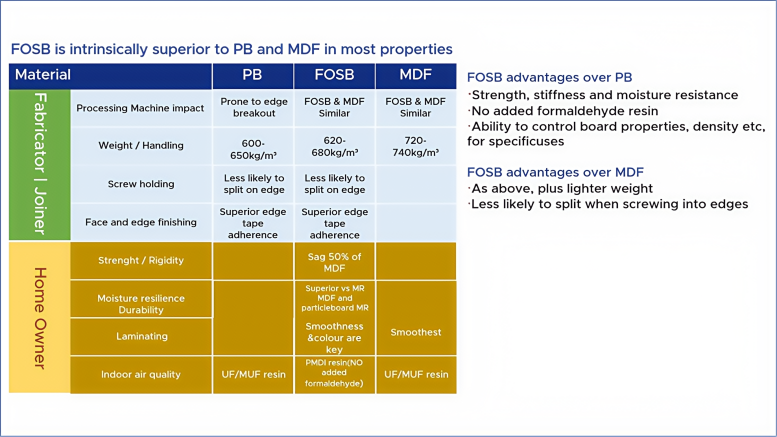

Why choose FOSB?