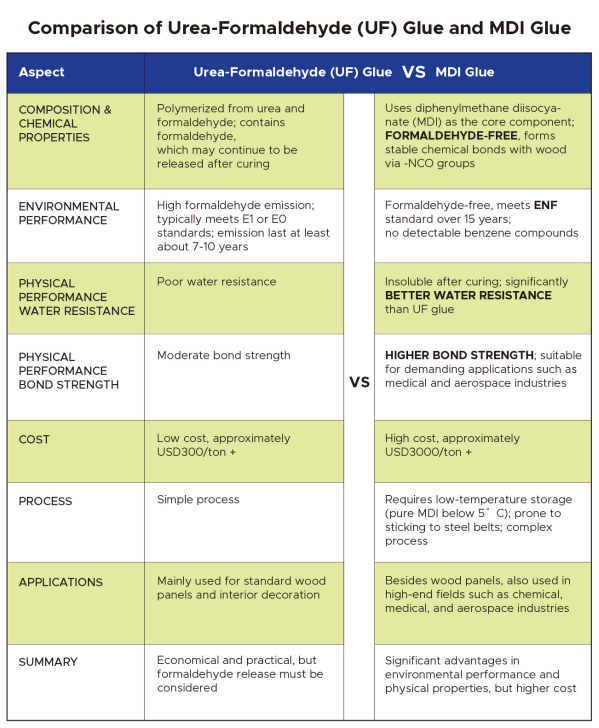

The environmental standards for home building materials are undergoing unprecedented upgrades. In this material revolution concerning respiratory health, MDI(Methylene diphenyl diisocyanate) and urea-formaldehyde (UF) adhesives have emerged as two of the most discussed options. While seemingly ordinary, these adhesives hold the key to indoor environmental safety—were you aware that conventional UF-bonded panels can emit formaldehyde at levels of 20–36 mg/100g, while MDI-bonded panels often tested as "not detected"? This difference is comparable to the gap between one-fifth of an apple’s natural emission and several dozen times that amount.

I. The Fundamental Safety Divide

The safety of MDI adhesive stems from its unique chemical properties. As a high-molecular synthetic material, MDI (diphenylmethane diisocyanate) is used not only in furniture manufacturing but also in medical applications such as artificial blood vessels and heart valves, where its biosafety has been rigorously validated. Products like OSB, FOSB, and particleboard made with MDI adhesive commonly comply with the CARB-NAF (No Added Formaldehyde) exemption—an international benchmark requiring formaldehyde emissions to be lower than those of solid wood, effectively eliminating formaldehyde pollution at the source. Research from global chemical leaders like Huntsman shows that MDI adhesive has extremely low volatility during production, ensuring both factory safety and end-product health.

In contrast, the issue with UF adhesive lies in its chemical composition. Even low-toxicity versions of this adhesive, synthesized from formaldehyde and urea, must keep free formaldehyde content within a limit of ≤0.3%. Studies by the Chinese Academy of Forestry reveal that typical UF-bonded panels emit formaldehyde in the range of 30–70 mg/100g.

Even with advanced scavengers and other technical interventions, emissions struggle to fall below 20 mg/100g. More critically, UF adhesive releases formaldehyde over the long term. Fluctuations in temperature and humidity can trigger continuous emission, making it a hidden and persistent source of indoor air pollution.

II. Context-Driven Value Choices

In home renovation, the choice between these adhesives directly impacts living health. For sensitive spaces such as children’s rooms and elderly living areas, MDI-bonded panels are clearly the better option. For instance, Dekek panels, made with pure MDI technology, emit formaldehyde at levels ≤0.003 mg/m³, comply with CARB and EPA certifications, and achieve "non-detect" status. Such products support "move-in-ready" renovation without long ventilation periods, ideal for today’s fast-paced lifestyles.

UF adhesive still finds a place in cost-sensitive scenarios. Melamine-modified low-formaldehyde UF resin can control emissions in MDF to around 20 mg/100g.

Commercial projects, however, must balance quality and brand image. High-end cafés and boutique hotels increasingly prefer the natural aesthetics and health assurances of MDI-bonded panels, which align with modern consumers’ pursuit of healthy living. Commercial projects using UF adhesives, on the other hand, face stricter environmental inspections.

Some regions now require all panel processors to meet low-VOC standards, imposing tighter restrictions on UF adhesive use.

III. The Final Decision in an Eco-Conscious Market

The building materials market in 2025 is undergoing profound transformation. High-end environmental standards such as ENF and F4-Star have become essential markers of quality housing. MDI-bonded panels, with formaldehyde emissions ≤0.025 mg/m³, easily surpass these requirements. Regulatory trends worldwide are pushing the industry toward formaldehyde-free alternatives. In this context, the technical advantages of MDI are translating into market advantages. For Dekek, the use of MDI adhesive has become a core competitive strength.

From a long-term value perspective, the initial investment in MDI pays off in health benefits. Although MDI-bonded products come at a higher unit cost than UF alternatives, they eliminate long-term air purification expenses and mitigate health risks associated with formaldehyde exposure. Calculations show that the extra cost of using MDI panels in a 100㎡ home can be recovered within 5–8 years through saved health expenses. The apparent cost advantage of UF adhesive often comes with the need for ongoing ventilation and purification—making its true cost potentially higher.

Choosing an adhesive is, at its core, choosing a lifestyle. As MDI bridges aerospace-grade safety with home materials, and UF continues striving to meet compliance standards, this material contest has transcended mere technicalities. In an age of health awareness, MDI represents not only advanced technology but also a sense of responsibility for family well-being. As Dekek panels meets both ENF and F4-Star certifications—true quality of life begins with protecting every hidden detail.