MDI LSB 2 / FOSB 2 Furniture Grade (Humid Area)

Laminated Strand Board (LSB) / Fine Surface Oriented Strand Board (FOSB) is a new type of panel. It is based on the ordinary Oriented Strand Board (OSB). Fine wood shavings are paved on both the upper and lower surfaces with the application of Polymeric MDI formaldehyde-free adhesive and then it is continuously flat-pressed. Compared with OSB, FOSB has a fine surface, which is smooth and flat. It has the advantage of being directly applicable for the veneering process and can meet the high-end customized needs with diversified panel styles.

- Overview

- Recommended Products

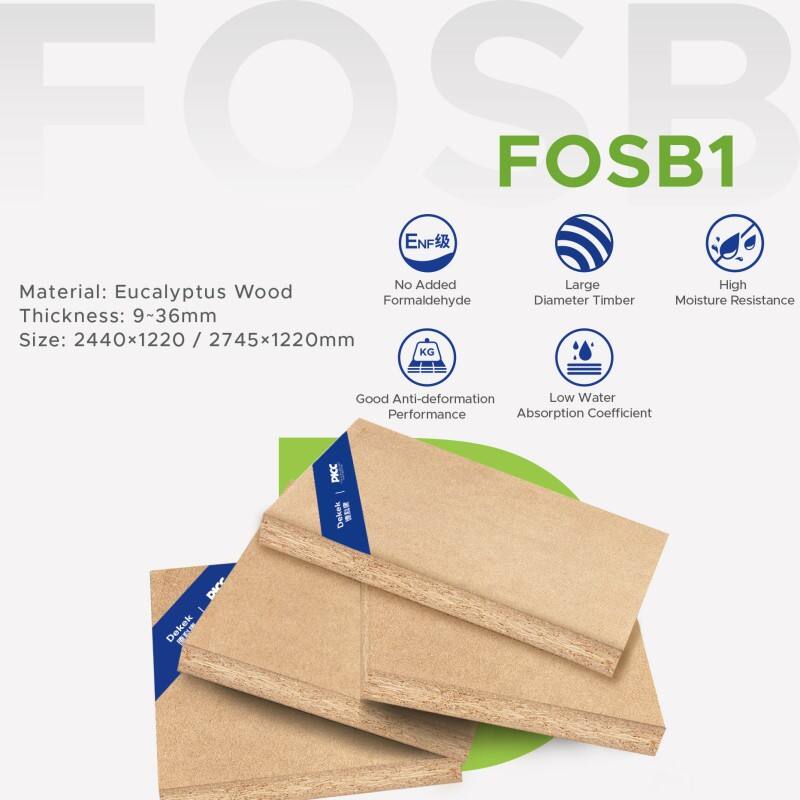

Product Information

Place of Origin |

Guangxi,China |

Brand Name |

Dekek |

Material |

Eucalyptus Wood / Pine Wood / Ceder Wood |

Adhesive |

Polymeric MDI |

Suface Treatment |

Sanded |

Waterproof Rating |

P10, 24h Thickness Swelling 6%-10% |

Density(KG/m³) |

650-680 |

Thickness (mm) |

9-36 |

Format (mm) |

2440*1220 2745*1220 1220*3050 1830*2440 |

Standard |

GB/T 41715—2022 |

Emission Class |

ENF CARB-ATCM 93120.2(a) Ultra-Low-Emitting Formaldehyde EPA-TSCA JAPAN F☆☆☆☆ |

Business Term

Minimum Order Quantity |

FCL |

Packaging Details |

Pallet |

Delivery Time |

30 days |

Payment Terms |

30% Deposit, 70%Balance |

Supply Ability |

1 million m³/year |

Samples |

Freely provided |

Installation |

Easy install with glue and clips & Nails |

Shipping Method |

Land freight/Sea freight |

Incoterms |

EXW,FOB,CIF |

| Test Item | Unit | Standard Specification | Test Result | Judgment Result |

|---|---|---|---|---|

| Moisture Content | % | 2~12 | 5.4 | Qualified |

| Static Bending Strength (Main Direction) | Mpa | ≥16 | 16.6 | Qualified |

| Static Bending Strength (Secondary Direction) | Mpa | ≥11 | 12.8 | Qualified |

| Modulus of Elasticity (Main Direction) | Mpa | ≥2300 | 2430 | Qualified |

| Modulus of Elasticity (Secondary Direction) | Mpa | ≥1500 | 2020 | Qualified |

| Internal Bond Strength | Mpa | ≥0.30 | 0.38 | Qualified |

| Surface Bonding Strength | Mpa | ≥0.8 | 1.08 | Qualified |

| Screw Holding Power | N | Panel Surface: ≥900 | 1160 | Qualified |

| Panel Edge: ≥600 | 910 | |||

| 24h Water Absorption Thickness Swell Rate | % | ≤20 | 14.9 | Qualified |

| Formaldehyde Emission (Perforator Method) | mg/100g | E₀: ≤0.5mg/100g | 0.12 | Qualified |

| Remarks | - | Note: The sample density is tested, and the result is 660kg/m³ | - | - |

Characteristics

- Low swelling in thickness

- Simple processing with conventional woodworking tools

- Smooth surface

- Special use in horizontal and vertical applications

- Increased resistance to humid conditions

Applications

- Furniture components

- Partitions

- Areas that require protection from moisture

- Bathroom and kitchen furniture

- Humid areas, kitchens / bathrooms

- Structural roof decking

- Various self-supporting components in construction and transportation

Key Features

- NO Added Formaldehyde

- Large Diameter logs

- High Moisture Resistance

- Good Anti-deformation Performance

- Low Water Absorption Rate