- Overview

- Recommended Products

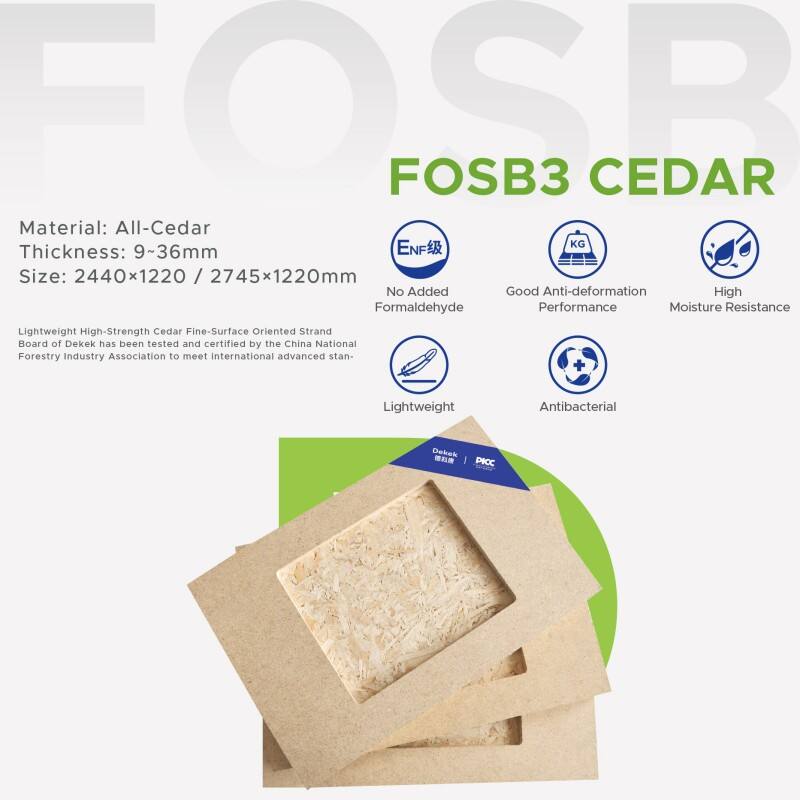

Product Information

Place of Origin: |

Guangxi,China |

Brand Name: |

Dekek |

Model Number: |

Fine Surface Oriented Strand Board (FOSB) Type 2 |

Material: |

Eucalyptus Wood |

Thickness: |

9-36mm |

Adhesive |

MDI |

Size: |

2440*1220/2745*1220mm |

Certification: |

FSC\CARB-ATCM\EPA-TSCA\JAPAN4STAR\ENF\CFCC |

Application |

Indoor Wall\Ceiling\Furniture |

Business Term

Minimum Order Quantity: |

One 40 inch Container |

Packaging Details: |

Pallet |

Delivery Time: |

30 days |

Payment Terms: |

30% Deposit, 70%Balance |

Samples: |

Freely provided |

Installation |

Easy install with glue and clips & Nails |

Shipping Method: |

Land freight/Sea freight/Express/Air freight |

Incoterms: |

EXW,FOB,CIF |

Specifications

The physical and mechanical properties of non - load - bearing fine - surface oriented strand board (F - OSB/2) in dry state shall meet the requirements below:

Item |

Unit |

Nominal thickness (t) range / mm |

||||

6 ≤ t ≤ 10 |

10 < t < 18 |

18 ≤ t ≤ 25 |

25 < t ≤ 32 |

32 < t ≤ 40 |

||

Static bending strength - main direction |

MPa |

20 |

18 |

16 |

14 |

12 |

Static bending strength - secondary direction |

MPa |

12 |

12 |

11 |

10 |

9 |

Elastic modulus - main direction |

MPa |

2700 |

2500 |

2300 |

2100 |

1900 |

Elastic modulus - secondary direction |

MPa |

1900 |

1700 |

1500 |

1300 |

1100 |

Internal bonding strength |

MPa |

0.35 |

0.33 |

0.30 |

0.28 |

0.26 |

24 - hour water absorption thickness expansion rate |

% |

14 |

14 |

14 |

14 |

14 |

Surface bonding strength |

MPa |

0.8 |

||||

Screw - holding force |

N |

The screw - holding force on the panel surface shall not be less than 900 |

||||

The screw - holding force on the panel edge shall not be less than 600 | ||||||

Applications

F-OSB/2 (Fine-Surfaced Oriented Strand Board Type 2) is a specialized engineered wood panel characterized by two core attributes: load-bearing performance tailored for dry environments and a smooth fine surface that streamlines finishing processes. Unlike F-OSB/3 (moisture-resistant load-bearing panels), it lacks durability against prolonged humidity or water exposure, so its applications are strictly limited to indoor or protected dry settings. Below is a detailed breakdown of its key uses:

Residential & Commercial Dry-Area Construction

As a cost-effective structural material for moisture-free indoor spaces, F-OSB/2 is widely applied in:

Interior wall systems

Serves as sheathing for non-wet interior walls (e.g., living rooms, bedrooms, office cubicles), providing stable support for drywall, plaster, or decorative panels. Its fine surface ensures flatness, avoiding unevenness in the final wall finish.

Upper-floor subflooring

Ideal for subfloors in upper levels of buildings (above ground floor, away from ground moisture) or dry zones (e.g., home offices, bedrooms). It bears the weight of floor finishes like hardwood, carpet, or luxury vinyl planks (LVP) without warping, thanks to its load-bearing capacity.

Dry-area ceiling decking

Used in attics, commercial office ceilings, or residential ceiling frameworks. It supports insulation, recessed lighting, and lightweight ceiling materials (e.g., ceiling tiles) while maintaining structural integrity in dry conditions.

Furniture & Interior Joinery

Its fine surface eliminates the need for extensive sanding, making it a practical choice for dry-environment furniture and woodwork:

Furniture structural components

Used for frames of sofas, beds, bookshelves, and dining tables—where structural stability is required but moisture exposure is minimal. It can be directly painted, stained, or laminated with veneers/melamine to match interior design styles.

Dry-area cabinetry

Suitable for bedroom wardrobes, home office storage cabinets, and living room display cabinets. Unlike kitchen or bathroom cabinets (which require moisture resistance), these units avoid water contact, allowing F-OSB/2 to perform reliably as a cabinet carcass material.

Industrial & Light-Duty Dry Applications

In controlled dry industrial settings, F-OSB/2 fulfills functional roles such as:

Workshop & storage structures

Used to build dry storage shelves, workshop workbenches, or non-load-bearing partitions in factories, warehouses, or garages with stable dry conditions. Its load-bearing capacity supports tools, dry goods, or lightweight equipment.

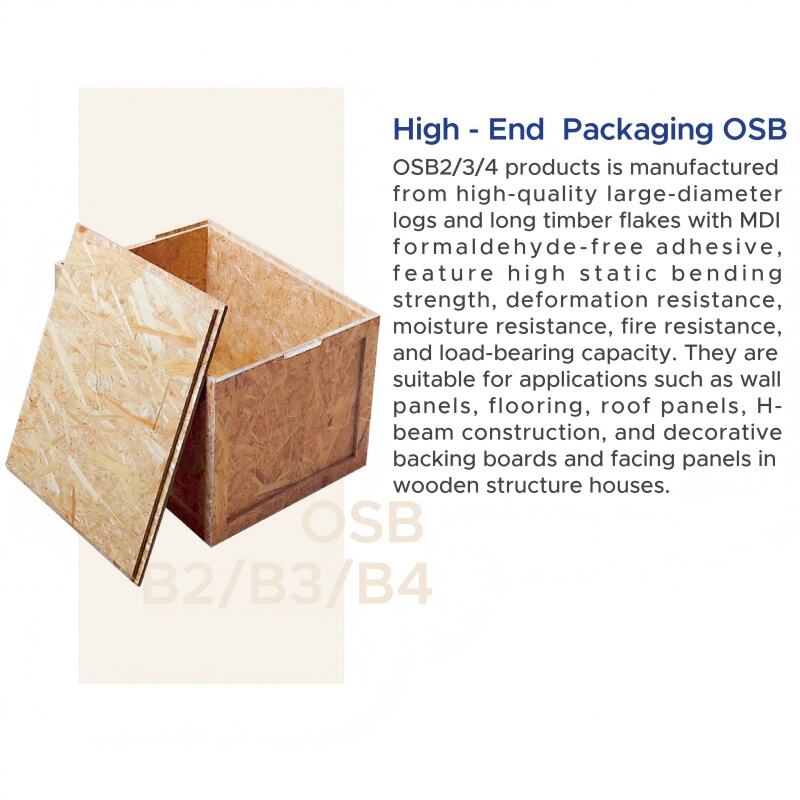

Dry-condition packaging

Manufactured into crates, boxes, or pallets for transporting/storing dry goods (e.g., electronics, textiles, dry construction materials) in climate-controlled facilities. It prevents deformation during transit but is unsuitable for outdoor or damp storage.

Specialty Dry-Scenario Uses

It also finds niche applications in dry-focused projects:

Modular dry units

Integrated into prefabricated interior modules (e.g., dry office pods, temporary dry storage lockers) where moisture exposure is completely controlled during production and installation.

Decorative backing panels

Serves as a smooth base for interior decorative elements (e.g., acoustic panels, wall murals, custom art installations) in dry spaces. Its fine surface ensures the decorative layer adheres evenly and maintains a polished appearance.

Competitive Advantage

NO Added Formaldehyde / Large Diameter Timber / High Moisture Resistance / Good Anti-deformation Performance / Low Water Absorption Coefficient