- Overview

- Recommended Products

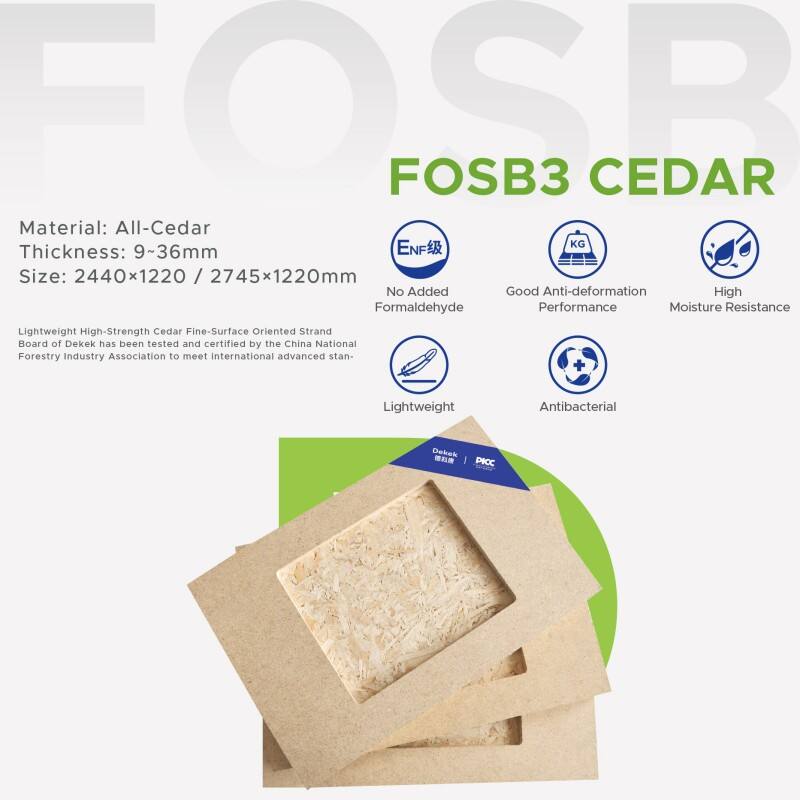

Product Information

Place of Origin: |

Guangxi,China |

Brand Name: |

Dekek |

Model Number: |

Fine Surface Oriented Strand Board (FOSB) Type 3 |

Material: |

All Cedar Wood |

Adhesive |

MDI |

Thickness: |

9-36mm |

Size: |

2440*1220/2745*1220mm |

Certification: |

FSC\CARB-ATCM\EPA-TSCA\JAPAN4STAR\ENF\CFCC |

Application |

Indoor Wall\Ceiling\Furniture |

Business Term

Minimum Order Quantity: |

One 40 inch Container |

Packaging Details: |

Pallet |

Delivery Time: |

30 days |

Payment Terms: |

30% Deposit, 70%Balance |

Samples: |

Freely provided |

Installation |

Easy install with glue and clips & Nails |

Shipping Method: |

Land freight/Sea freight/Express/Air freight |

Incoterms: |

EXW,FOB,CIF |

Specifications

Physical and Mechanical Property Requirements for Load-Bearing Fine-Surfaced Oriented Strand Board (F-OSB/3 Type) in Wet Condition below:

Item |

Unit |

Nominal thickness (t) range / mm |

||||

6 ≤ t ≤ 10 |

10 < t < 18 |

18 ≤ t ≤ 25 |

25 < t ≤ 32 |

32 < t ≤ 40 |

||

Static bending strength - main direction |

MPa |

20 |

18 |

16 |

14 |

12 |

Static bending strength - secondary direction |

MPa |

13 |

12 |

11 |

10 |

9 |

Elastic modulus - main direction |

MPa |

2700 |

2500 |

2300 |

2100 |

1900 |

Elastic modulus - secondary direction |

MPa |

1900 |

1700 |

1500 |

1300 |

1100 |

Internal bonding strength |

MPa |

0.45 |

0.40 |

0.35 |

0.32 |

0.30 |

24 - hour water absorption thickness expansion rate |

% |

8 |

6 |

7 |

7 |

6 |

Surface bonding strength |

MPa |

0.8 |

||||

Screw - holding force |

N |

The screw - holding force on the panel surface shall not be less than 900 |

||||

The screw - holding force on the panel edge shall not be less than 600 | ||||||

Applications

F-OSB/3 (Fine-Surfaced Oriented Strand Board Type 3) is a specialized engineered wood panel designed for load-bearing use in wet or high-humidity conditions, with a fine surface that enhances its adaptability across multiple sectors.

Residential and Commercial Construction

It serves as a core structural material in areas exposed to moisture. Typical uses include subflooring (especially in bathrooms, kitchens, or ground-floor spaces prone to occasional water exposure), wall sheathing (for exterior walls or interior wet zones like laundry rooms), and roof decking (under shingles or waterproof membranes, where it resists moisture from rain or condensation). Its load-bearing capacity supports structural loads (e.g., floor weight, roof pressure) while withstanding humidity.

Furniture and Cabinetry Manufacturing

The fine surface of F-OSB/3 eliminates the need for additional sanding or surfacing, making it suitable for furniture frames, cabinet carcasses, and storage units—even those used in damp environments (e.g., bathroom vanities, kitchen base cabinets near sinks). It provides stable structural support and can be directly laminated with veneers, melamine, or paint for a finished appearance.

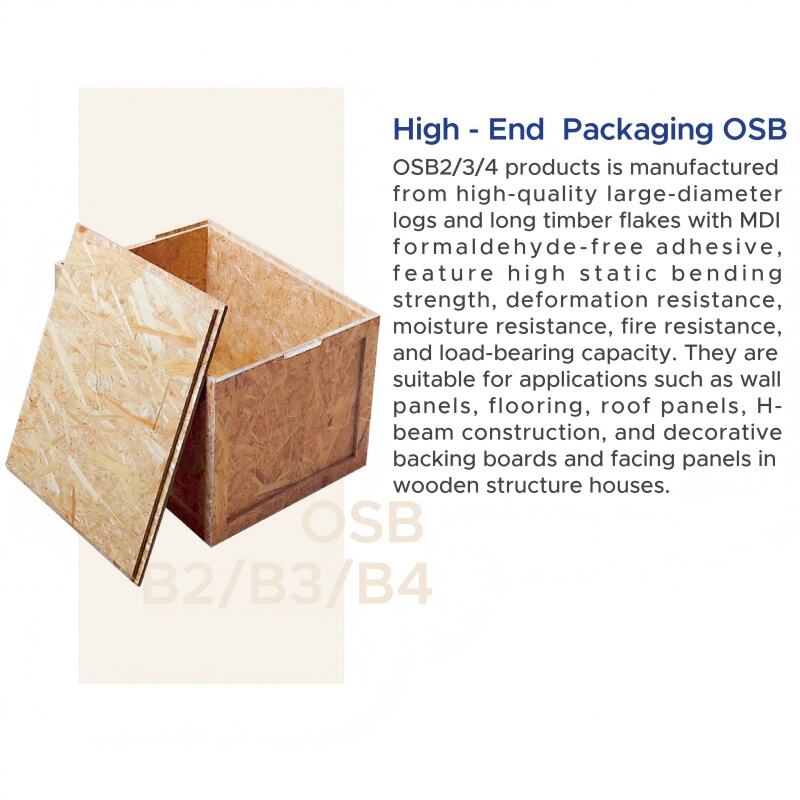

Packaging and Transportation

For heavy-duty packaging or transport components (e.g., crates for industrial equipment, pallets for goods stored in humid warehouses), F-OSB/3 offers high strength and moisture resistance. It prevents warping or structural failure caused by damp storage or transit conditions, ensuring the safety of packaged items.

Specialty Applications

It is also used in modular construction (prefabricated walls/floors that may be exposed to weather during installation), temporary structures (e.g., job site offices in rainy regions), and interior design elements (e.g., decorative wall panels requiring both durability and a smooth base). In these scenarios, its combination of load-bearing capability, moisture resistance, and fine surface meets both functional and aesthetic needs.

Competitive Advantage

No Added Formaldehyde / Lightweight / Antibacterial / Good Anti-deformation Performance / High Static Bending Strength