The construction and industrial sectors continue to evolve with innovative materials that deliver superior performance across demanding applications. Among these advanced solutions, FOSB panels have emerged as a game-changing building material that combines exceptional durability with versatile functionality. These engineered panels represent a significant leap forward in structural board technology, offering enhanced moisture resistance and load-bearing capabilities that make them ideal for specialized construction projects.

Premium FOSB panels distinguish themselves through their sophisticated manufacturing process and carefully selected raw materials. Unlike traditional oriented strand boards, these panels undergo specialized treatment processes that enhance their structural integrity while maintaining cost-effectiveness. The result is a building material that performs exceptionally well in environments where conventional panels might fail or deteriorate over time.

Modern construction professionals increasingly recognize the value of selecting materials that can withstand harsh conditions while maintaining structural stability. This growing awareness has positioned FOSB panels as a preferred choice for architects, engineers, and contractors working on projects that demand reliable performance in challenging environments. Understanding which applications benefit most from these premium panels can help decision-makers optimize their material selection strategies.

Bathrooms and kitchens represent some of the most challenging environments for building materials due to constant exposure to moisture, temperature fluctuations, and humidity variations. Traditional subflooring materials often struggle in these conditions, leading to warping, swelling, or structural degradation over time. FOSB panels excel in these applications because their enhanced moisture resistance prevents the common issues associated with water exposure.

The superior dimensional stability of these panels ensures that flooring installations remain flat and secure even when subjected to significant moisture variations. This stability translates directly into reduced maintenance costs and longer-lasting installations. Professional installers particularly appreciate how these panels maintain their structural integrity without requiring excessive sealing or protective treatments that add complexity and expense to projects.

Furthermore, the consistent performance of FOSB panels in high-moisture environments provides peace of mind for both contractors and homeowners. The reduced risk of callbacks and warranty claims makes these panels an intelligent investment for projects where moisture exposure is inevitable. This reliability factor becomes especially important in commercial kitchen applications where operational continuity depends on structural stability.

Basement environments present unique challenges that demand materials capable of withstanding ground moisture, temperature variations, and potential flooding scenarios. FOSB panels demonstrate exceptional performance in these underground applications where traditional materials might compromise over time. Their enhanced moisture resistance makes them particularly valuable for basement subflooring and wall sheathing applications.

The structural characteristics of these panels provide excellent support for finished flooring systems while maintaining their integrity in high-humidity conditions. This performance consistency helps prevent the buckling and warping issues commonly associated with basement installations. Property developers working on basement finishing projects increasingly specify FOSB panels to ensure long-term performance and minimize future maintenance requirements.

Additionally, the dimensional stability of these panels in varying moisture conditions makes them ideal for foundation applications where precise measurements and consistent performance are critical. The ability to maintain structural specifications despite environmental challenges represents a significant advantage for construction professionals working in challenging below-grade conditions.

Industrial facilities require flooring systems capable of supporting substantial loads while maintaining structural integrity under continuous stress. FOSB panels excel in these demanding applications due to their superior load-bearing capacity and resistance to compression-related deformation. Manufacturing facilities, warehouses, and distribution centers benefit significantly from the enhanced structural performance these panels provide.

The engineered construction of these panels distributes loads more effectively than traditional alternatives, reducing the risk of localized failure points that can compromise entire flooring systems. This load distribution characteristic becomes particularly valuable in applications involving heavy machinery, storage systems, or high-traffic scenarios where consistent performance is essential for operational efficiency.

Professional engineers appreciate the predictable performance characteristics of FOSB panels when designing structural systems for industrial applications. The consistent load-bearing specifications allow for more precise calculations and reduced safety factors, often resulting in more economical overall structural designs without compromising safety or performance standards.

Commercial roofing systems demand substrates that can support significant loads while maintaining dimensional stability under varying weather conditions. FOSB panels provide exceptional performance as roofing substrates due to their enhanced structural characteristics and resistance to environmental stresses. Large commercial buildings, industrial facilities, and institutional structures benefit from the reliable performance these panels deliver.

The superior fastener-holding capacity of these panels ensures secure attachment of roofing membranes and other components, reducing the risk of system failures that can result in costly repairs and operational disruptions. This holding power remains consistent even under the thermal cycling conditions common in roofing applications, providing long-term reliability for building owners and facility managers.

Roofing contractors increasingly specify FOSB panels for projects requiring enhanced performance characteristics because they reduce installation complications and provide superior long-term stability. The panels' resistance to thermal expansion and contraction helps maintain seal integrity and prevents the fastener backing-out issues that can compromise roofing system performance over time.

Marine environments present extreme challenges for building materials due to salt air exposure, high humidity levels, and potential storm surge impacts. FOSB panels demonstrate exceptional performance in these harsh coastal conditions where traditional materials often fail prematurely. Waterfront construction projects, marine facilities, and coastal residential developments benefit significantly from the enhanced environmental resistance these panels provide.

The moisture resistance characteristics of these panels make them particularly valuable for dock construction, marine equipment buildings, and other structures that face direct or indirect saltwater exposure. Unlike conventional panels that may deteriorate rapidly in marine environments, FOSB panels maintain their structural integrity and dimensional stability despite challenging conditions.

Coastal construction professionals appreciate how these panels reduce maintenance requirements and extend service life in demanding marine environments. The reduced need for protective treatments and frequent replacements makes FOSB panels a cost-effective choice for projects where environmental durability is paramount to operational success.

Agricultural buildings face unique environmental challenges including humidity from livestock, chemical exposure from fertilizers and feed, and temperature fluctuations from seasonal weather patterns. FOSB panels provide excellent performance in these demanding agricultural applications where durability and environmental resistance are essential for operational efficiency.

Dairy barns, poultry houses, and grain storage facilities benefit from the enhanced moisture resistance and structural stability these panels provide. The ability to maintain performance despite exposure to ammonia, cleaning chemicals, and high humidity levels makes FOSB panels particularly valuable for livestock housing applications where conventional materials might deteriorate quickly.

Farm building contractors increasingly recommend these panels for agricultural construction projects because they reduce long-term maintenance costs and provide reliable performance in challenging environments. The dimensional stability of FOSB panels helps maintain proper ventilation system function and structural alignment, which are critical factors for successful agricultural operations.

The dimensional stability of FOSB panels represents one of their most significant advantages in critical applications where precise measurements and consistent performance are essential. This stability results from advanced manufacturing processes that create more uniform internal structures compared to traditional panel products. Applications requiring tight tolerances and consistent dimensions benefit substantially from this enhanced stability characteristic.

Precision construction projects such as modular housing, prefabricated components, and high-end finish installations rely on materials that maintain their specified dimensions throughout the construction process and beyond. The superior dimensional stability of these panels reduces installation complications and helps ensure that finished projects meet exacting specifications.

This stability characteristic becomes particularly valuable in applications involving complex joinery or precision-fit components where even minor dimensional changes can compromise system performance. Manufacturers of prefabricated building components increasingly specify FOSB panels because their dimensional consistency improves production efficiency and reduces quality control issues.

Effective moisture management represents a critical performance factor for building materials used in challenging environments. FOSB panels excel in moisture management through their enhanced resistance to water absorption and their ability to maintain structural integrity in high-humidity conditions. This performance advantage makes them particularly valuable for applications where moisture control is essential for long-term success.

The moisture management capabilities of these panels extend beyond simple water resistance to include superior performance in vapor transmission applications. This characteristic helps prevent condensation-related problems that can compromise building envelope performance and indoor air quality. Building professionals working on energy-efficient construction projects particularly value this enhanced moisture management capability.

Additionally, the consistent moisture management performance of FOSB panels helps prevent the mold and mildew issues that can develop when building materials retain excess moisture. This prevention capability is especially important in applications involving vulnerable populations such as schools, healthcare facilities, and senior living developments where indoor air quality is paramount.

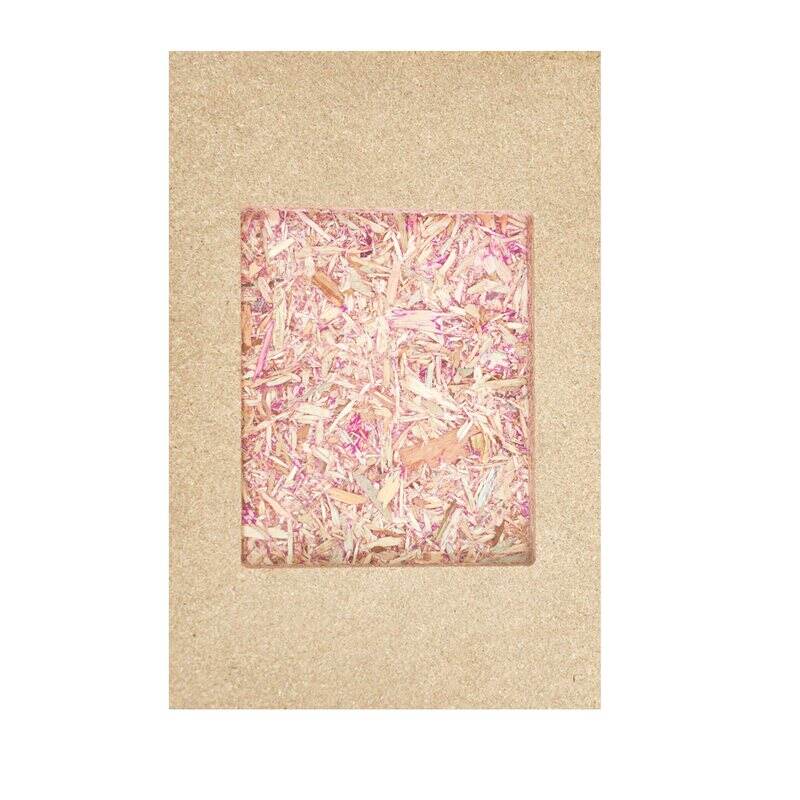

FOSB panels feature enhanced manufacturing processes and specialized treatments that improve their moisture resistance and structural performance compared to standard OSB panels. These improvements result in superior dimensional stability, increased load-bearing capacity, and better performance in challenging environmental conditions. The advanced engineering of FOSB panels makes them particularly suitable for applications where standard panels might not provide adequate long-term performance.

FOSB panels demonstrate excellent performance in exterior applications due to their enhanced moisture resistance and dimensional stability. They maintain their structural integrity when exposed to weather conditions and provide reliable performance as wall sheathing, roof decking, and other exterior structural components. However, like all wood-based panels, they should be properly installed with appropriate weather barriers and finishes according to manufacturer recommendations for optimal long-term performance.

Yes, FOSB panels are well-suited for high-traffic commercial flooring applications due to their superior load-bearing capacity and resistance to compression-related deformation. Their enhanced structural characteristics make them ideal for retail spaces, office buildings, and other commercial facilities where consistent performance under heavy foot traffic is essential. The panels maintain their dimensional stability and structural integrity even under demanding commercial use conditions.

Proper installation of FOSB panels requires attention to manufacturer specifications regarding spacing, fastening patterns, and environmental conditions. While these panels offer superior performance characteristics, following established installation practices ensures optimal results. Key considerations include proper acclimation, appropriate fastener selection, and adequate ventilation in enclosed applications. Professional installation typically yields the best results and helps maximize the performance advantages these premium panels provide.