Abstract

Fine-surface Oriented Strand Board (F-OSB) is an innovative product developed from traditional Oriented Strand Board (OSB). Its core feature is the use of fine strands on the surface layers, allowing it to retain the excellent structural performance of OSB while achieving a high-quality surface suitable for direct finishing. As market demand for the decorative and functional properties of panels increases, F-OSB has become a key product bridging structural and decorative materials. This article aims to systematically review and conduct a comparative analysis of the classification systems and technical requirements for F-OSB as outlined in the National Standard of China (GB/T 41715-2022) and the China National Forest Products Industry Association Group Standard (T/CNFPIA 3023-2022). Based on existing research, it provides an in-depth analysis of its physical and mechanical properties to offer references for production, application, and standard selection.

1. Overview of the F-OSB Related Standard System

The standardization of F-OSB reflects the coordinated efforts of national and industry bodies to promote the rapid development of new materials. Currently, two main standard documents regulate F-OSB, each with different focuses and complementing each other.

(1) National Standard GB/T 41715-2022 "Oriented Strand Board": This is the fundamental and comprehensive national standard for OSB in China, released in October 2022 and implemented in May 2023. Its most significant aspect is the formal inclusion of F-OSB into the national standard system for the first time. This standard modifies and adopts the international standard ISO 16894:2009, with important additions tailored to China's context. Key revisions include "adding the definition of Fine-surface Oriented Strand Board (F-OSB)", "adding classification by 'surface strand coarseness'", and "adding classifications and corresponding physical/mechanical performance requirements for three types of fine-surface strand boards". This marks the official technical recognition and specification of F-OSB as a formal product category at the national level.

(2) Group Standard T/CNFPIA 3023-2022 "Fine-surface Oriented Strand Board": Released by the China National Forest Products Industry Association and implemented on May 31, 2022. This standard was published earlier than the national standard and demonstrates stronger industry specificity and a piloting role. It focuses specifically on the F-OSB product, and its technical requirements may be more detailed or stringent, reflecting the technical consensus and market orientation of leading industry enterprises regarding high-quality F-OSB products.

Together, these two standards create an ecosystem for F-OSB where the "national standard sets the framework, and the group standard promotes premium quality". In practice, GB/T 41715-2022 serves as the basic threshold and general reference, while T/CNFPIA 3023-2022 provides more specialized guidance for enterprises producing high-performance, high-value-added F-OSB products.

2. Core Differences Comparison: Standard Classification, Performance Requirements, and Application Positioning

2.1 Differences in Classification Systems

GB/T 41715-2022 employs a multi-dimensional classification method, whereas the group standard focuses on grading the product itself. The table below clearly illustrates the differences:

Comparison Dimension |

GB/T 41715-2022 "Oriented Strand Board" |

T/CNFPIA 3023-2022 "Fine-surface Oriented Strand Board" |

Basis of Classification |

Integrates multiple dimensions: conditions of use, load-bearing performance, surface roughness, sanded/unsanded, etc. |

Specifically for F-OSB products, graded according to physical/mechanical performance and surface quality. |

Classification Related to F-OSB |

1. By surface strand coarseness: Divided into Regular OSB (R-OSB) and Fine-surface OSB (F-OSB). |

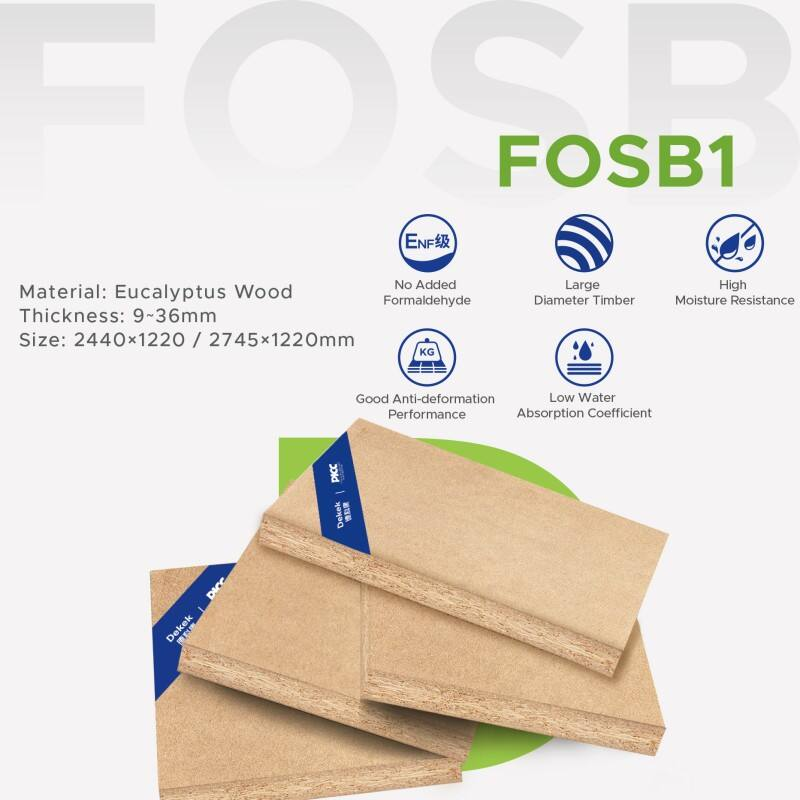

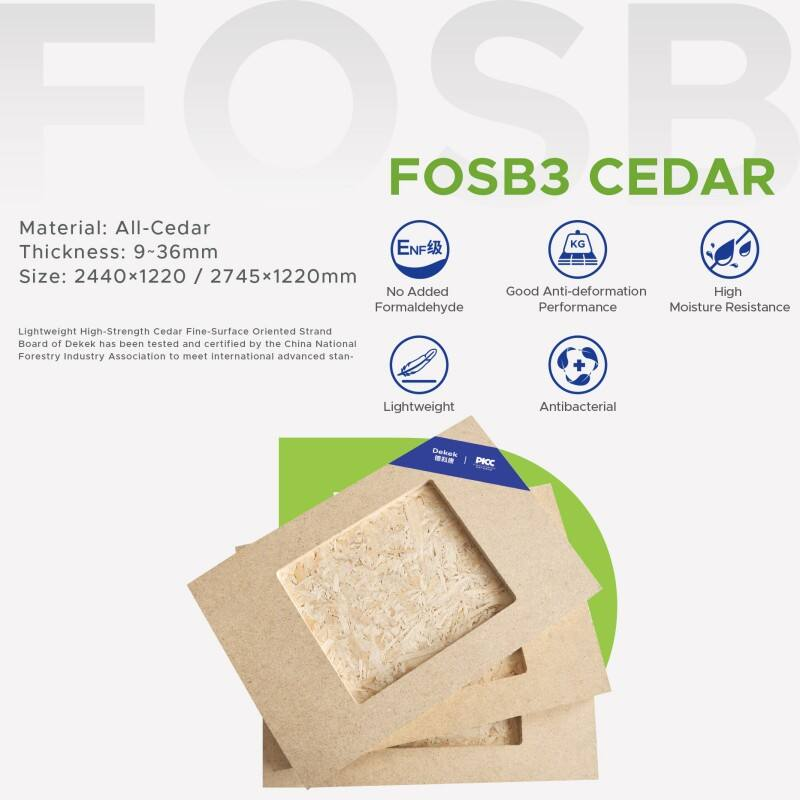

The standard title itself is "Fine-surface Oriented Strand Board". Its core classification is presumed to be different quality grades such as FOSB1, FOSB2, FOSB3. |

Core Purpose |

To establish a universal classification framework covering all Oriented Strand Boards (including R-OSB and F-OSB), enabling correspondence and alignment with international standards (e.g., OSB/1-OSB/4 in EN 300) and incorporating new products. |

To establish a product quality grading system specifically for the F-OSB market segment, potentially exceeding the basic requirements of the national standard, guiding high-end manufacturing. |

Key Interpretation:

● Regarding "FOSB/L": Within the national standard framework, "FOSB/L" is a specific category, denoting F-OSB for non-load-bearing applications in dry conditions (L). This aligns with the positioning of "OSB/1" in international classifications (general-purpose boards for interior fitments in dry conditions). It emphasizes basic decorative function, with relatively lower requirements for mechanical strength.

● Regarding "FOSB1, FOSB2, FOSB3": The meaning of the numbers "1, 2, 3" in these two sequences within the national and group standards differs significantly and is easily confused.

○ FOSB/1, /2, /3 in the National Standard: The numbers primarily relate to "conditions of use and load-bearing performance". For example, FOSB/2 likely corresponds to "load-bearing boards for use in dry conditions", and FOSB/3 to "load-bearing boards for use in humid conditions", following the grading logic of traditional OSB/2 and OSB/3. Its core is structural performance grading.

○ FOSB1, FOSB2, FOSB3 in the Group Standard: The numbers more likely represent "comprehensive quality grades", a sequence evaluating overall physical/mechanical performance, appearance quality, environmental indicators, etc. FOSB3 typically represents the highest grade product within that standard system.

2.2 Physical/Mechanical Performance Requirements and Application Positioning

Although specific performance index values require consulting the original standards, the trend of requirements can be inferred from the standard structure and related research:

● FOSB/L (National Standard): As a non-load-bearing panel, its requirements for physical/mechanical properties (such as modulus of rupture, modulus of elasticity, internal bond strength) are the lowest among F-OSB types. Its core value lies in providing a high-quality surface suitable for secondary processing like laminating or painting. It is mainly used in non-structural applications in dry environments, such as furniture backs, internal partitions, and decorative wall panels.

● FOSB/1, /2, /3 (National Standard) and FOSB1, FOSB2, FOSB3 (Group Standard): These categories all have explicit mechanical performance requirements, but with different emphases.

○The National Standard series (/1, /2, /3) performance requirements are closely aligned with structural applications. For example, FOSB/3 (load-bearing for humid conditions) would focus on assessing the retention of mechanical properties (like internal bond strength) after exposure to humid conditions or boiling.

○The higher grades in the Group Standard (e.g., FOSB3), while meeting or exceeding the national standard's structural requirements, impose stricter regulations on surface quality and environmental indicators (e.g., VOC emissions). Related research indicates that the surface layer density of F-OSB is higher than that of regular OSB, giving it superior performance in indices like modulus of rupture (MOR) and modulus of elasticity (MOE), with smaller performance differences between length and width directions and better homogeneity.

Product Category / Grade |

Core Characteristics |

Typical Application Scenarios |

FOSB/L (National Std.) |

High-quality surface, basic physical properties. |

Indoor, dry, non-structural components: furniture, cabinet carcases, decorative wall panels. |

FOSB/2 or FOSB1 (Nat'l/Group Std.) |

Good structural performance + finishable surface. |

Structural and decorative components in dry environments: indoor floor underlayment, load-bearing partitions in dry areas, load-bearing parts for custom furniture. |

FOSB/3 or FOSB3 (Nat'l/Group Std.) |

Excellent structural performance (moisture resistant) + premium finishable surface. |

Humid environments or high-demand scenarios: kitchen/bathroom cabinet carcases (requiring proper edging), balcony cabinets, interior sheathing for light wood frame construction, high-end custom cabinetry. |

Application Positioning Summary:

3. In-depth Analysis of Technical Performance: F-OSB vs. Traditional OSB

Research from institutions like Nanjing Forestry University reveals the mechanisms behind the performance differences between F-OSB and traditional OSB at micro and macro levels.

(1) Density Profile and Mechanical Properties: F-OSB uses fine strands for the surface layers, resulting in a significantly higher surface layer density compared to regular OSB. In three-point bending tests, this high-density surface layer gives F-OSB higher modulus of rupture (MOR) and more balanced modulus of elasticity (MOE), with smaller performance differences between length and width directions than regular OSB.

(2) Strain Distribution and Failure Mode: Research using Digital Image Correlation (DIC) strain analysis found that under load:

○ Traditional OSB: Internal strain tends to diffuse towards the core layer. Failure can occur randomly at the surface, core, or other locations, exhibiting a random fracture pattern.

○ F-OSB: Due to its dense surface layers and the relatively large density gradient towards the core, strain has difficulty diffusing into the core and tends to concentrate on the upper and lower surface layers. This leads to a failure mode that is almost exclusively surface layer fracture. This characteristic means the quality of F-OSB's surface layers is crucial for its overall load-bearing capacity.

(3) Deformation Behavior: Research also notes that traditional OSB exhibits the inherent elastic and plastic deformation processes of wood under load, whereas F-OSB shows less obvious plastic deformation, displaying a somewhat more "brittle" fracture characteristic. This necessitates different considerations for the application design of F-OSB under long-term loads.

4. Conclusion and Outlook

Fine-surface Oriented Strand Board (F-OSB) successfully combines the strength of structural panels with the surface quality of decorative panels through technological innovation. The current standard system, centered on GB/T 41715-2022 and T/CNFPIA 3023-2022, provides clear guidance for the product standardization and market grading of F-OSB.

● For Manufacturers and Purchasers: It is essential to clearly distinguish between the national standard's "condition/performance classification" (e.g., FOSB/L, /1, /2, /3) and the group standard's "quality grade classification" (e.g., FOSB1, 2, 3). In contracts and technical specifications, the applicable standard number, product code, and grade must be explicitly stated, for example, "FOSB/3 conforming to GB/T 41715-2022" or "FOSB3 grade conforming to T/CNFPIA 3023-2022".

● For Designers and Applicators: Understanding the mechanical characteristics of F-OSB—"high-strength surface layers, concentrated strain"—is crucial. When using it for structural or load-bearing components, its surface layer performance should be fully utilized, noting its slightly different failure mode compared to traditional OSB. Its excellent surface makes it a "finishable structural panel", greatly expanding the application of OSB in visible areas.

● Future Outlook: With the development of prefabricated construction and the custom furniture industry, demand for F-OSB that combines high strength, high weather resistance, low formaldehyde/no added formaldehyde, and excellent surface decorability will continue to grow. Future standard upgrades and technological research will likely focus on higher environmental grades (e.g., formaldehyde-free), better moisture resistance, and base material requirements for specific finishing processes (e.g., thin wood veneering, metal composite).

In summary, F-OSB represents an important direction in the development of composite functional wood-based panels. Correctly understanding and applying its standard system and performance characteristics will help all parties in the industrial chain better develop, select, and utilize this high-performance material, promoting its application in broader fields.